Hygienic/Sanitary line

Our range of heat exchangers for hygienic/sanitary applications uses corrugated tube heat exchangers specially designed for these applications in the food, pharmaceutical, body care and cosmetic industries.

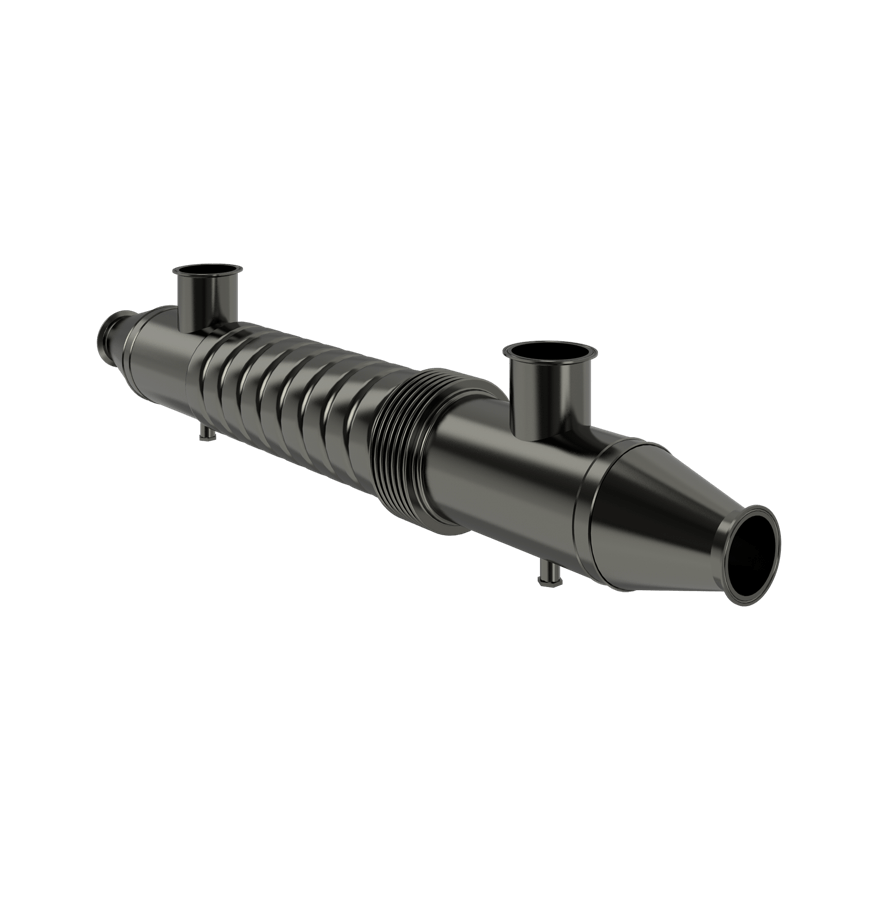

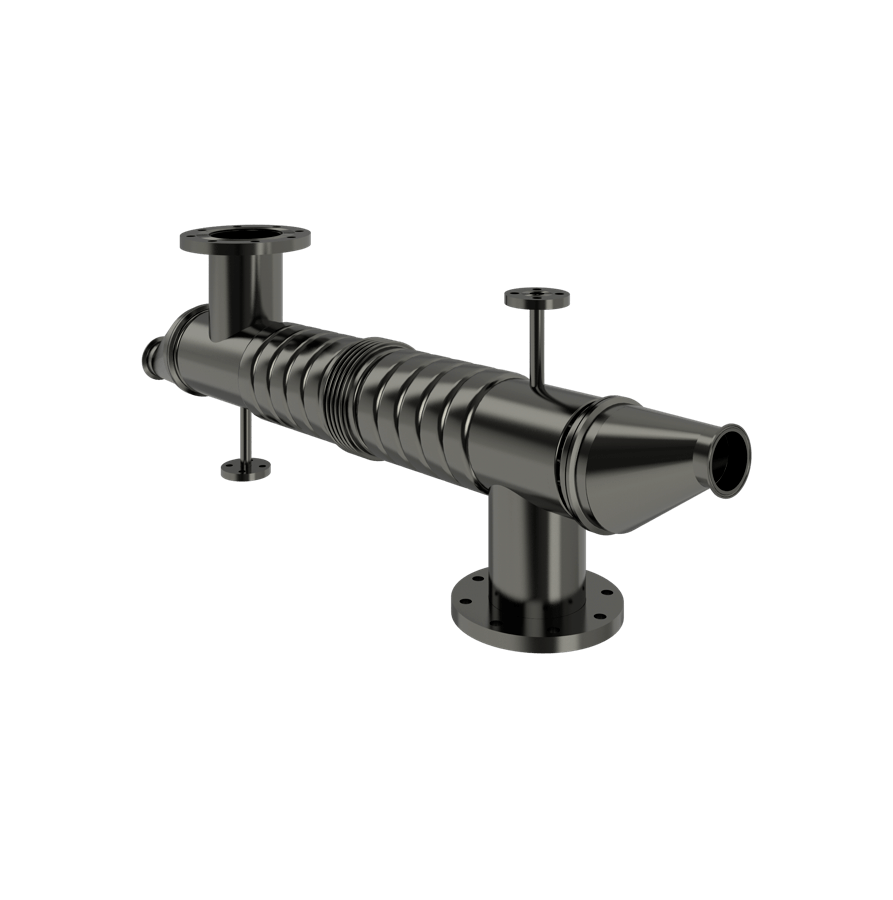

Multitube

Multitube

Multi-tube design heat exchanger, with removable tube bundle, double tubesheets, pitched installation for self-draining, hygienic/sanitary design according to 3A standards, with corrugated or plain tubes, recommended for processing low and medium viscosity fluids, homogeneous fluids or fluids with small particles in suspension.

Temperature conditions 180ºC and 25 bar pressure (others on request).

Manufactured in austenitic stainless steel, superaustenitic, duplex and titanium.

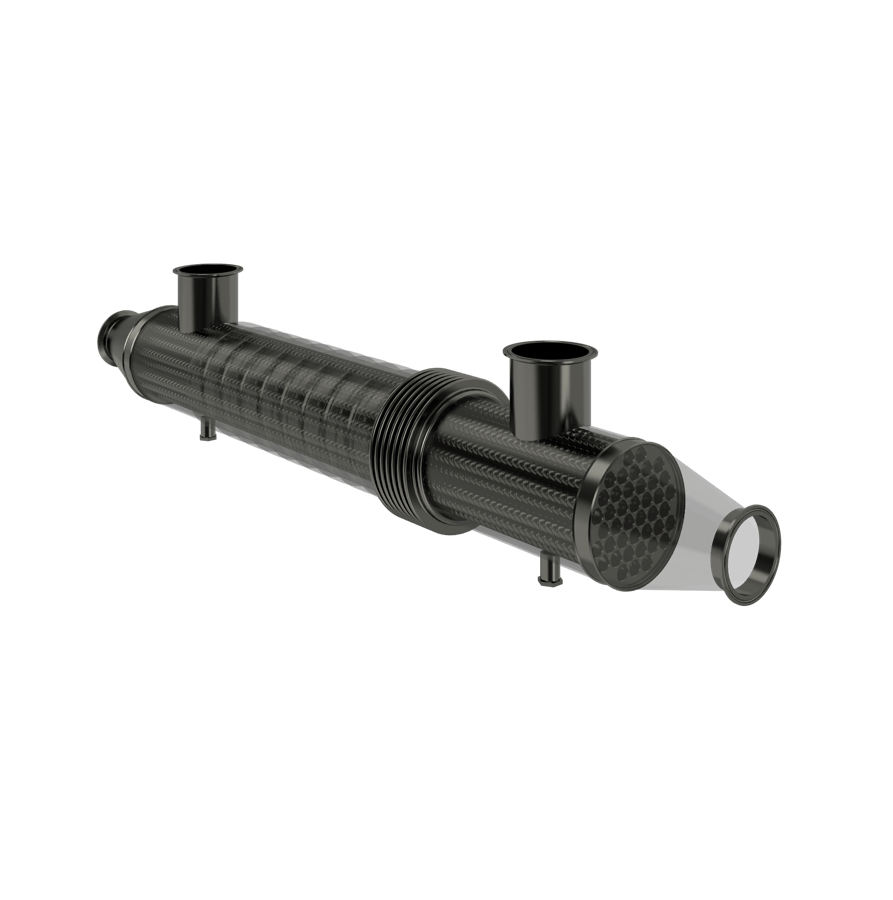

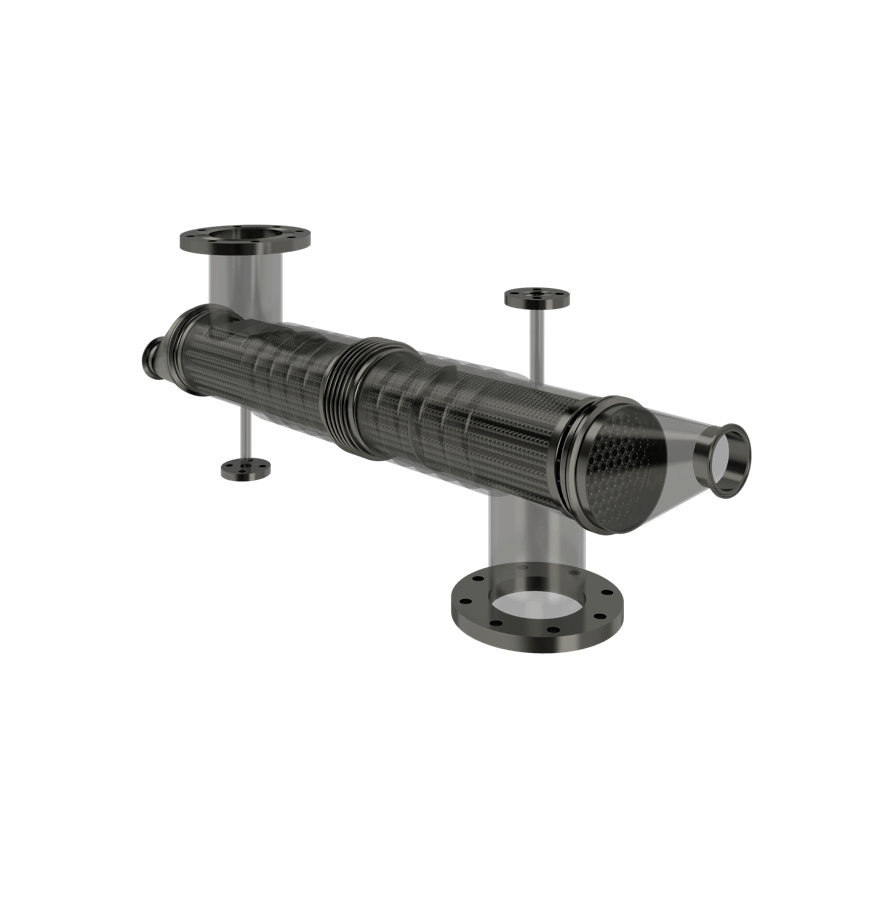

Multitube

Multitube

Multi-tube design heat exchanger, with welded or removable tube bundle, hygienic/sanitary designed according to 3A standards, with corrugated or plain tubes, recommended for processing low and medium viscosity fluids, homogeneous fluids or fluids with small particles in suspension.

Temperature conditions 180ºC and 25 bar pressure (others on request).

Manufactured in autenitic stainless steel, superaustenitic, duplex and titanium.

Pharmagrade

Pharmagrade

Multitube heat exchanger designed according to ASME BPE standards, with double tubesheets to avoid cross contamination, with welded or removable tube bundle, welded or seamless corrugated or smooth tubes, electropolished or mechanically polished (tube side surface roughness Ra<= 0.25 / 0.4 / 0.5 microns) and self-draining design.

Temperature conditions 180ºC and 25 bar pressure (others on request).

Manufactured in austenitic stainless steel (other materials on request).

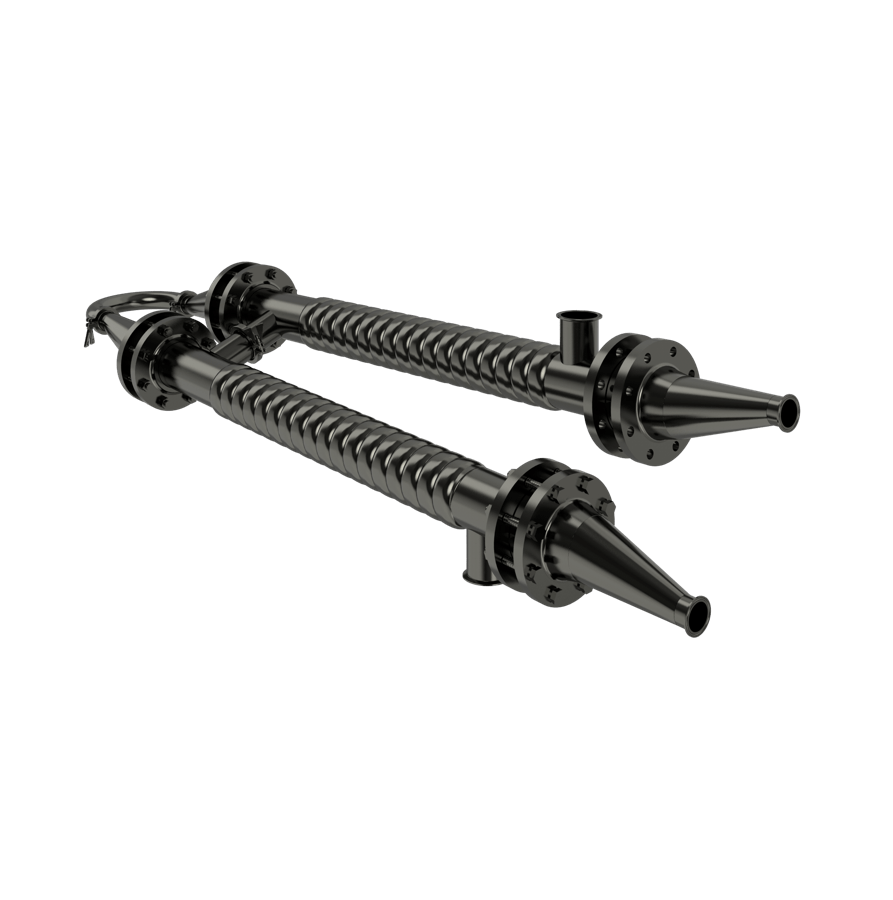

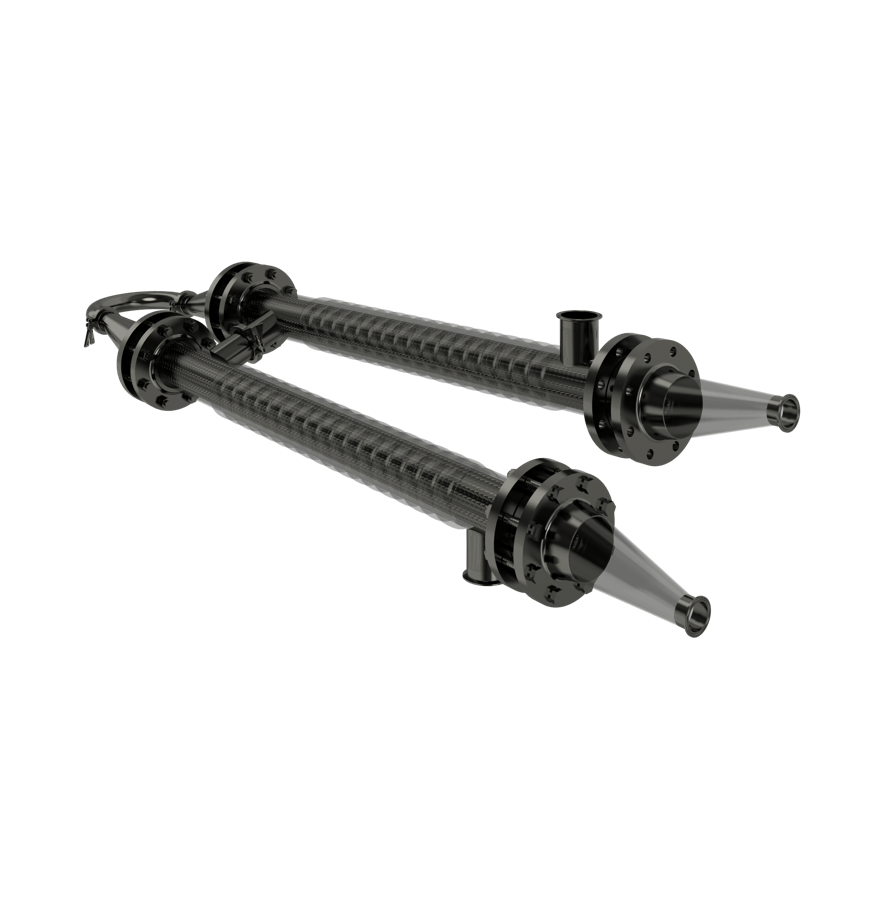

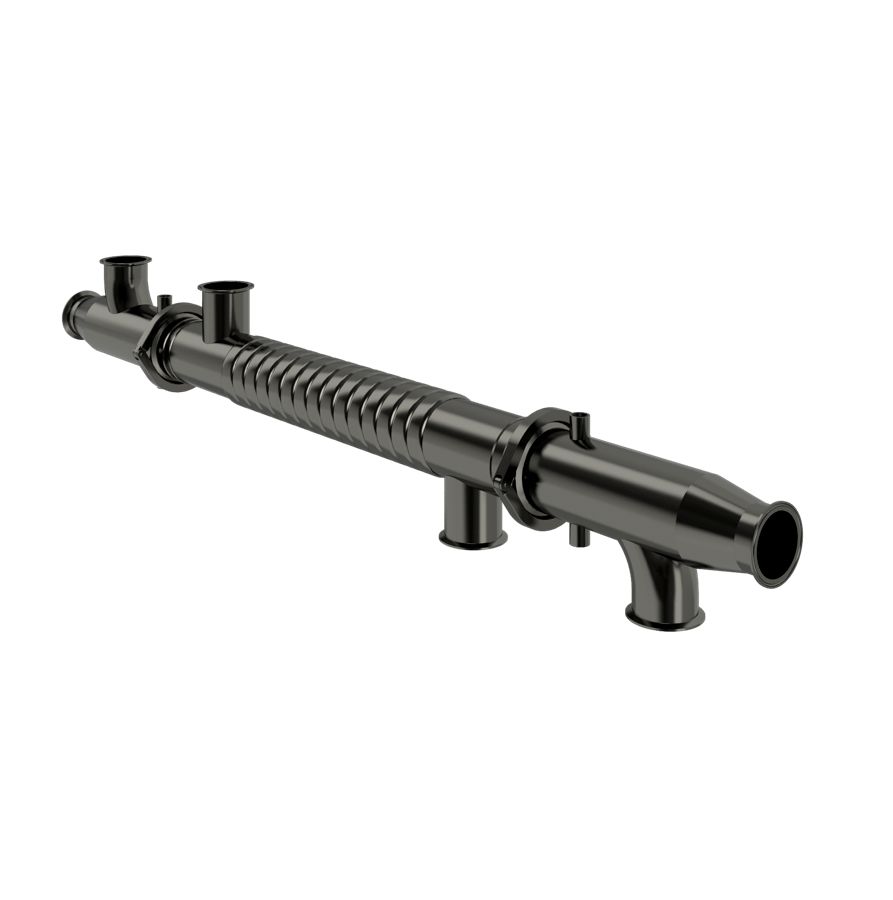

Monotube

Monotube

Monotube heat exchanger for hygienic/sanitary duties according to 3A standards, to process fluids with solids in suspension like fibers, cells or particulates (diced products).

Temperature conditions 180ºC and 25 bar(g) pressure (others on request).

Manufactured in austenitic stainless steel, superaustenitic, duplex and titanium.

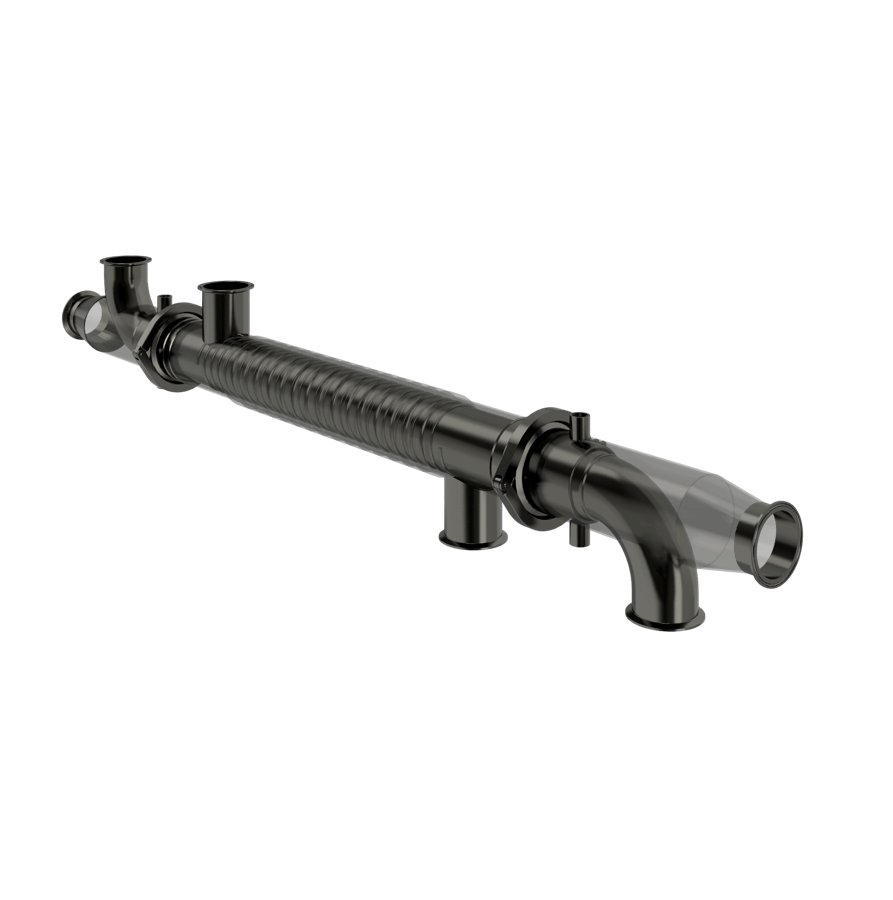

Multicanal

Multicanal

The heat exchanger is formed by 3 or 4 concentric corrugated tubes. Specially recommended for processing concentrates and fluids of high viscosity and low acidity, homogeneus or with small particles in suspension. Hygienic/sanitary designed according to 3A standards.

Temperature conditions 180ºC and 25 bar(g) pressure (others on request).

Manufactured in austenitic stainless steel, superaustenitic, duplex and titanium.

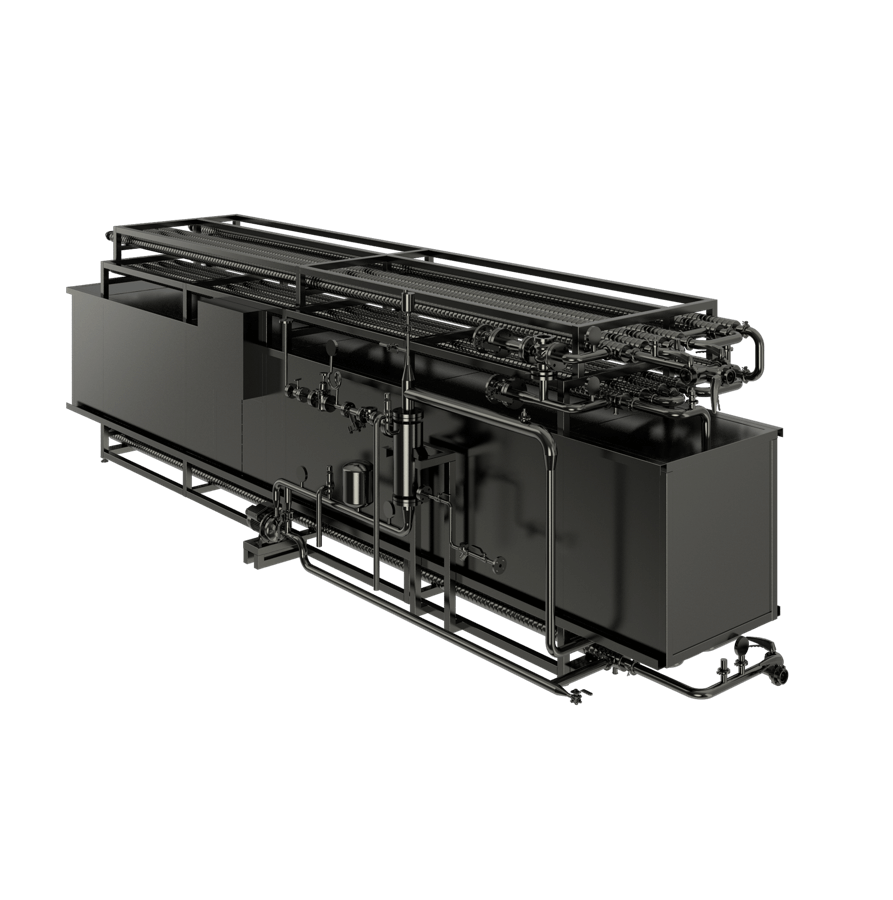

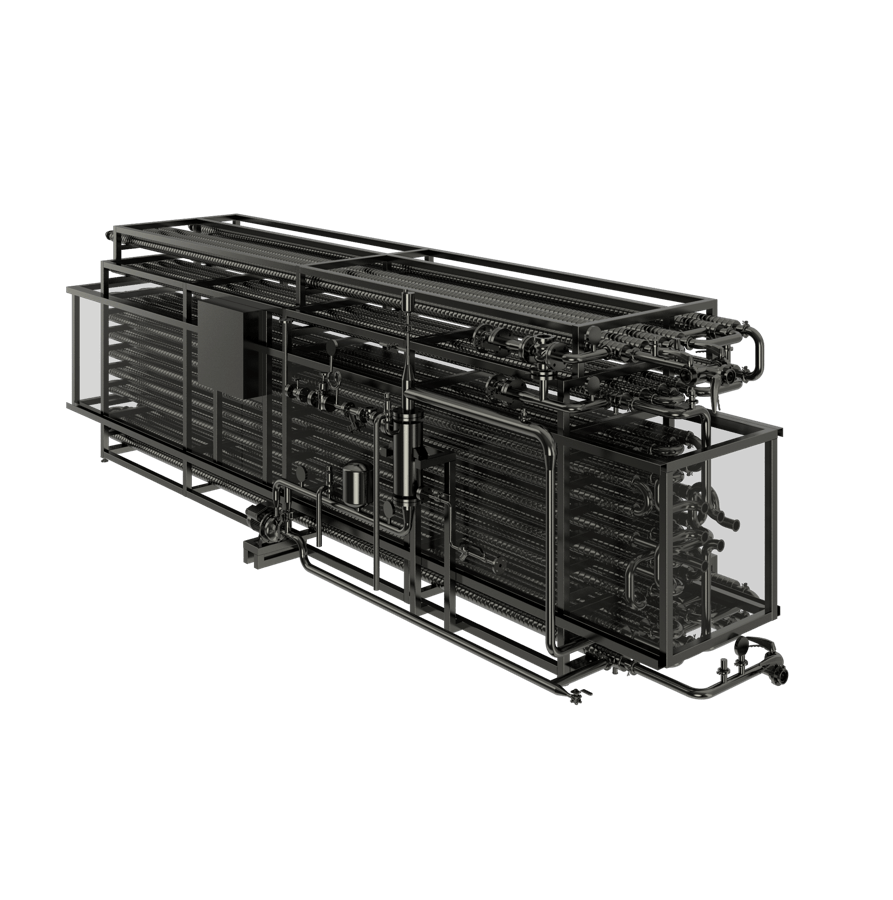

Processing plant

Processing plant

Complete pasteurization or sterilization plants for the food industry, dairy industry, etc., with XLG® heat exchangers as well as high quality equipment (pumps, valves, flowmeters, homogenizers, etc.), tanks, electrical cabinet and control system, all on a self-supporting structure.